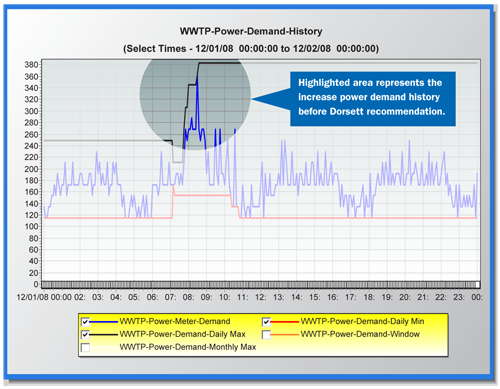

Yadkinville’s WWTP personnel sought to understand why their electricity bill had such a large “demand” billing charge. After connecting the plant’s existing power meter to their InfoScan SCADA system, it was readily apparent a very atypical peak demand was being set every month, as seen in the graph below.

Evaluation:

After an extensive investigation, Dorsett engineers were able to determine the peak demand spike was caused by WWTP personnel manually starting a backup aeration blower for one hour every week. This one piece of equipment increased the month’s peak demand by an additional 130 KWD!

Solution:

Dorsett Controls engineers determined that changing the schedule of the blower test to an off-peak demand time would eliminate the excessive cost incurred as a result of the backup blower testing.

Result:

$7,473.44 savings during winter months (8)

$6,348.56 savings during summer months (4)

$13,822.00 total savings over a 12-month period